FULL SERVICE PARTNER

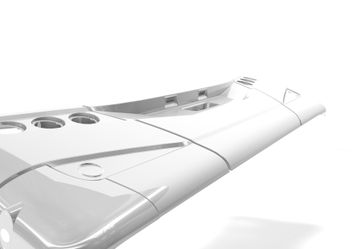

SERVICE-DRIVEN, STRONG IN PROCESSING AND GLOBALLY STRUCTURED.At PARAT Technology, we are always ready to meet current challenges in all of your projects and take responsibility for the entire process cycle: from the idea through to market readiness. We specialize in high-quality plastic trim parts and combine the most advanced technologies with longtime expertise.

Thanks to our unique technology and surface finishing portfolio, we can offer you an optimal approach within the framework of a holistic solution when it comes to plastic composites.

Thanks to our unique technology and surface finishing portfolio, we can offer you an optimal approach within the framework of a holistic solution when it comes to plastic composites.

Projects with PARAT Technology

We support our partners from the initial idea to the discontinuation of their product. All steps take place in-house, from construction and design to after sales.

-

Can PARAT Technology provide comprehensive support for my project?

We support our partners from the initial idea to the discontinuation of their product. All steps take place in-house, from construction and design to after sales.

-

Do I have a direct contact person?

Our project management team is on hand to answer all your questions and concerns. Order processing can also provide precise information on the status of your product at a later date.

-

Can I come to PARAT Technology with a short-term project?

We can also discuss enquiries at short notice with you. Please get in touch with us using the contact details provided.

-

Will my products arrive on time and reliably?

Our optimised process steps and high machine capacities enable us to achieve high delivery reliability. Coordination and communication between our sites also run smoothly.

-

Does PARAT Technology consider my individual case?

We always approach new enquiries with an openness to technology. This means that we work with our partners to find the perfect solution for planned projects.